Industry X.0 Canvas

The Great Restructuring is pushing the manufacturing strategy towards flexible operations, resilient supply chain, and sustainable re-shoring causing a paradigm shift in the way we skill, staff, and operate. The imperative to transform has led organizations to pilot various initiatives with almost nothing to show for it.

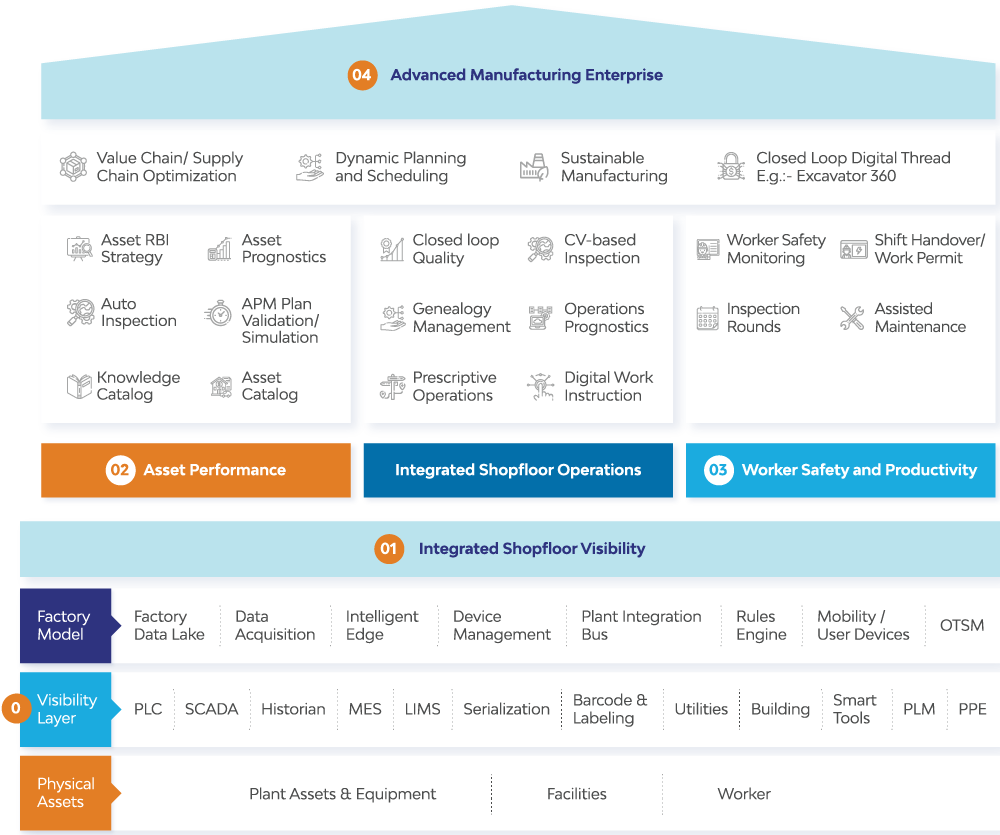

At LTI, we have helped our clients come out of this pilot purgatory. IXC is our methodology, IP’s & ecosystem to digitize factory assets and processes to provide integrated visibility & enable autonomous operations helping the customer achieve tangible business outcomes.

Highlights

Digitize your factory assets

Leverage IXC to add a layer of intelligence covering all assets for better connectivity and accessibility

Unlock a vault of insights

Improve visibility into key data that is embedded in manufacturing machines and processes

Turn your company into a manufacturing powerhouse

Unleash the true power of data by unifying scattered data seamlessly across different silos and turn this into actionable information for improvement and growth

Eliminate friction between key stakeholders using conversational AI

Use the power of AI to enable conversational commerce in manufacturing

Future of Manufacturing

- Visibility

- Integrated Insights

- Asset

- Operations

- Worker

- Cognitive Manufacturing Enterprise

IXC provides a persona-centric business perspective to data democratization and citizen development. It achieves this goal in a step-by-step pragmatic way by driving the manufacturing system’s maturity in terms of data visibility and integration. It builds on this integrated visibility layer by building asset twin, process twin, and worker twin data models. These three pillars along with the integrated visibility layer and conversational AI lead to a cognitive manufacturing enterprise of tomorrow.

Services

Consulting

IXC Road Map

Platform Services

Manufacturing Innovation Studio for MVPs

Scale Up Hyperscalers, Hybrid Cloud, Data Products, Data Science

Brochure

Case Studies

Blogs

PoV

Whitepapers