Is there a chip shortage, and How Can Businesses Overcome it?

An omnipresent, omniscient and omnipotent semiconductor

Semiconductors are everywhere and have become an essential part of our lives. They power our coffee machines, ATMs, mobiles, and most electronic devices. Today, chips facilitate the widespread adoption of technologies such as Artificial Intelligence (AI), quantum computing, and advanced wireless networks like 5G. We know that the pandemic drove a big fraction of the workforce to recreate the office at home, school systems switched to virtual learning and spending on home entertainment, such as TVs and game consoles went through the roof. While the macroeconomic and geopolitical environment continues to push the boundary to meet these demands, the industry should continuously look for ways to evolve and deliver ground-breaking performance with the intervention of advanced technologies.

Is there a chip shortage?

For the last three decades, semiconductors have been increasingly sought after due to the scarcity of raw materials, unavailability of resources , declined prices of the finished product, and pandemic.

There have been serious supply shortages of semiconductors globally leading to what is being referred to as the semiconductor shortage crisis, which was coined by experts in reference to the 70’s oil crisis. There are six main participants of the global output of the semiconductor industry: US, China, Taiwan, South Korea, Japan, and Europe. According to Deloitte (2021) , most of the top chip design companies rely on the Asia Pacific region to manufacture their semiconductor chips. Over 70% of the total semiconductor chip manufacturing is collectively owned by the two most influential chip manufacturers: Taiwan Semiconductor Manufacturing Corporation (TSMC of Taiwan) and Samsung (South Korea).

However, the semiconductor chip shortage of 2021 sparked a crisis in the global economy. Apple, the world’s largest consumer of chips, delayed the launch of the iPhone 12 by two months; Samsung, the second-largest buyer and producer, had to do the same for its new smartphones. The global auto industry lost billions of dollars in revenue in 2021 . The current worldwide chip shortage is posing unfathomable challenges across every industry.

What is causing this shortage?

There are various factors contributing to the semiconductor shortage crisis, but the key issues are:

Demand for chips skyrocketed

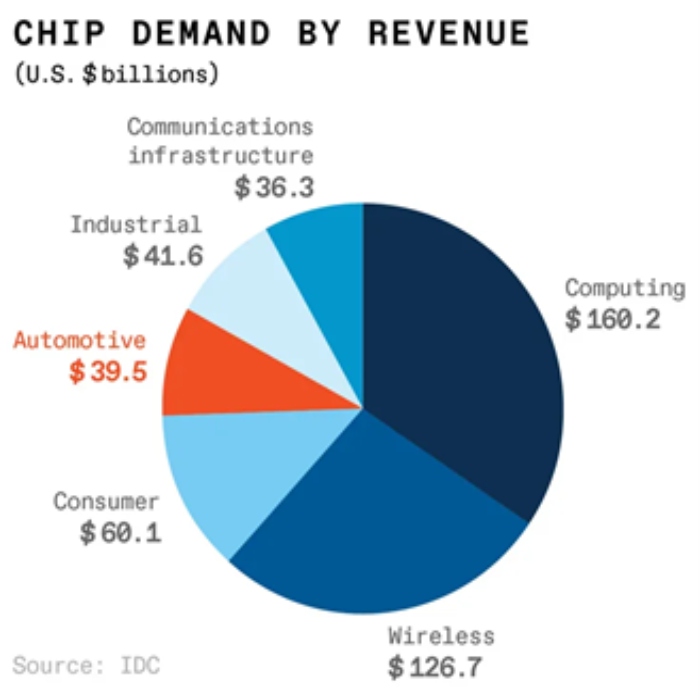

The pandemic has fundamentally changed our behavior and increased our dependency on electronics. Consequently, the demand for electronic devices skyrocketed, and these devices are heavily dependent on numerous chips for various functionalities like display, power, connectivity, etc. In addition, there has been a growing demand for chips in automotive and industrial applications and for the production of 5G technology. Hence, these put additional pressure on the chip manufacturers to meet the increasing demand.

Long lead times with complex supply chain

Everyone understands that chip production is a highly complex and time-consuming process, and it can take months, or even years, to design and manufacture a new chip. A semiconductor chip’s average manufacturing cycle time may take up to 26 weeks. To begin with, around 12 weeks are required to manufacture the semiconductor wafer; however, this might take up to 20 weeks for advanced semiconductor manufacturing processes. The next procedure is called back-end assembly, test, and packaging (ATP), which may take up to 6 weeks. Ultimately, the lead time between a customer placing an order and receiving the final product may take up to 26 weeks.

Semiconductors’ global supply chain includes distributed manufacturing facilities across different continents and countries. Consequently, the companies must deal with different tax laws, import controls, and diverse regulations. Though the core activities are highly concentrated in certain regions offering economies of scale, it has ultimately created two types of vulnerabilities:

- Large-scale disruptions can occur because of a single point of failure

- Global access to suppliers or customers can be impaired due to geopolitical tensions

Adding fuel to the fire, chip shipments were delayed due to the reduced number of flights and airways closure across the globe during the lockdowns.

Source: Bloomberg

What are the long-term solutions?

Many companies are looking for creative solutions to address the semiconductor shortage crisis. While there is no silver bullet to solve current short-term issues, the suggestions outlined below can help companies avoid the next crisis and become more resilient in the future.

Reimagined supply chain resilience

Companies have started devising many ways to increase supply chain flexibility. The basic and foundational recommendations that we suggest to our customers are:

- Define, understand, and decide the type of chips required and their supply chain ecosystem

- Understand their production lead time

- Empathize with their suppliers’ situations (to avoid overordering, false volume commitments, etc.)

- Establish a well-defined analytics-driven control tower expertise

One of the ways to improve the supply chain resiliency is by producing some chips in-house and having products compatible with different types of chips according to availability. Some are also looking to increase production by building new factories or expanding existing ones.

Stronger technology roadmaps

Creating stronger technology roadmaps will increase transparency and allow companies to steer their product development more strategically. Companies may decide to re-engineer chips, hold discussions jointly with the OEMs to identify opportunities for drop-in components, or collaborate with OEMs to reduce variations in the large-volume discrete and analog devices across different vehicle components.

Manufacturing improvements

The recent crisis has demonstrated how Just-in-Time (JIT) can have devastating impacts under supply chain disruptions. For instance, the shortage of a few cents worth of chips can stop the entire production line of a car worth $30K. To optimize efficiency, the supply chains that were built on JIT concept must be revisited and redesigned to meet the current and future demands at scale. Also, the semiconductor chip production process can be simplified and handled entirely by AI. While it takes six months for humans to build one processor, AI can do it in less time.

Digitization of processes

IoT is an effective and creative solution for semiconductor shortage. Disruptions can be predicted through real-time data sharing and analysis. Furthermore, problems can be identified ahead of time and dealt with accordingly, improving the efficiency and resilience of the supply chain. By leveraging data and advanced algorithms, semiconductor chip manufacturers can predict demand and optimize their manufacturing processes, reducing waste and inefficiencies.

Industry 5.0

Smart manufacturing has already changed the paradigm of the semiconductor manufacturing process, backed up by advanced skills and technologies. Industry 4.0 has been the pioneer in revolutionizing the smart manufacturing process. Although industry 4.0 has several values, Industry 5.0 with a set of advanced technologies, such as collaborative robots and cognitive technologies, will accelerate chip manufacturing and improve efficiency significantly. Industry 5.0 can also help organizations to focus on offering personalized services while utilizing resources prudently. Semiconductor chip manufacturers are increasingly adopting Industry 5.0 to achieve sustainable and improved manufacturing processes.

How can technology provide long-term solutions?

True North Star for Semiconductors

Based on the industry headwinds such as fast-changing tech trends, consumer behavior changes, digital ways of working, environmental concerns, localization and supply chain impacts, and other factors like Covid-19 acceleration and last mile fulfillment and engagement, we have envisaged the true north vectors for the semiconductor industry. True north is a journey of transformation that takes the organization to the point of arrival through a series of tech and process interventions. We have highlighted a couple of them below:

Transforming supply chain processes

With the help of digital enablers, supply chain processes can be transformed in the following ways:

- Visibility through reimagined Control Tower Experience

- Resilience through continuous and collaborating planning

- Intelligence through AI/ML-enabled proactive decisions

- Sustainability through scorecards for tracking sustainability metrics

Transforming the semiconductor industry through digital technologies

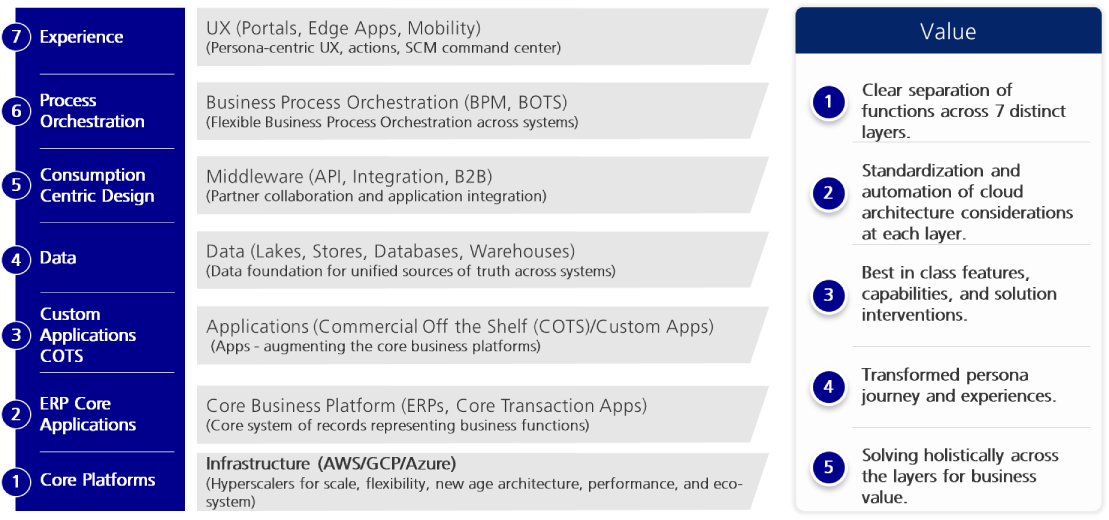

The rainbow architecture framework provides a holistic approach to identifying the core technologies across 7 layers critical to defining future reference architecture. The framework provides a simple template that can be used to answer fundamental questions to drive the IT estate strategy.

Use Cases

With our industry and domain-led DNA and next-gen capabilities around full-stack IT and Operational Technology (OT) strengths, LTIMindtree is constantly building various value propositions, solutions, and accelerators addressing objectives like factories-of-the-future, Product-as-a-Service (PaaS), sustainable operations, and digital thread. Over the years, we have solved customers’ pain points across operating domains like engineering design and testing, substrate manufacturing, water fabrication, sort, assembly, test, and probe model house. The below diagram provides a snapshot of what we have done for various semiconductor customers.

Fig: Key use cases solved by LTIMindtree for various semiconductor companies

Conclusion

Overall, the chip shortage is a complex issue with no easy solutions. It will require cooperation and collaboration across industries to address the problem and ensure a stable supply of semiconductor chips for the future. The recent chip shortage might be rare, but it can be tackled by adopting advanced digital technologies.

We at LTIMindtree strongly believe that the confluence of exponential technologies like metaverse, digital twins, AI, 5G, IoT, 3D printing, etc. will help companies stay nimble and compete effectively in dynamic market conditions but also drive efficiency across product lifecycle at scale.

Are you a part of the semiconductor industry and looking to re-engineer your business processes, devise immersive next-gen experiences, and create new revenue streams? Our team of experts can help. Contact us today to discuss custom solutions tailored to your specific needs.

More from Rakesh Suresh

IntroductionChatGPT is an unprecedented gamechanger, especially in terms of breaking product…

Latest Blogs

A closer look at Kimi K2 Thinking, an open agentic model that pushes autonomy, security, and…

We live in an era where data drives every strategic shift, fuels every decision, and informs…

The Evolution of Third-Party Risk: When Trust Meets Technology Not long ago, third-party risk…

Today, media and entertainment are changing quickly. The combination of artificial intelligence,…